Project Overview

There have been several identical seal failures on subsea valve actuators in the North Sea and other global subsea installations. When the valves are actuated open, excessive hydraulic fluid is leaked to sea. To allow these wells to continue producing, inherently mechanical lock-out devices (LAOTs) have been installed as a temporary measure. Unfortunately, this removes the functionality from the platform to open and close the valves and will no longer respond to an emergency shut-down situation meaning that the valves are not operable without costly ROV intervention.

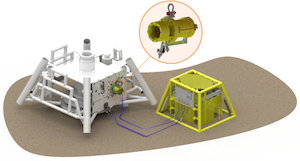

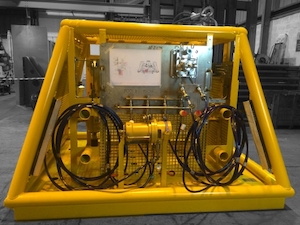

MMA engineered and manufactured the PCOL (Platform Controlled Override Linear) system as a permanent solution to overcome all the problems of temporary LAOTs. Three diver-installable PCOL systems were successfully deployed in 2015.

Key features of the PCOL system include:

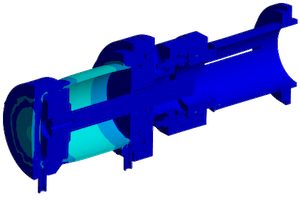

- 100% designed and manufactured by MMA

- Designed for permanent installation and full reinstatement of leaking actuator valves and hence permanent Tree reinstatement

- 20-year design life

- Powered supplied from XT SCM (Subsea Control Module) with 3000 psi working pressure

- Compatible with all bayonet type actuators

- All components made of Super Duplex, Inconel 625 & Inconel 718

- For use with 5” and 2” actuators

- Dual redundancy on all seals

- Zero compression set on seals

- Advanced surface treatments on key surfaces

- Contamination tolerant

- Diver installed (ROV deployable version also been developed)

- Restores full valve and Tree functionality

- Valve controlled by same SCM directional control valve and software as host (failed) actuator

- Closure time of the valves are designed to meet emergency subsea disconnect (ESD) criteria

- Included in the regular subsea installation, repair and maintenance (IRM) campaign

- Auxiliary Skid provide multiple modes of intervention and compensation

- Qualified in accordance with API 17D internal and hyperbaric pressure testing

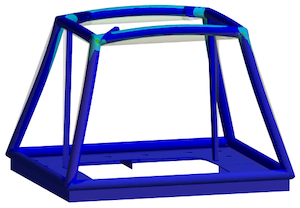

- Following the successful deployment of the first three PCOL systems, MMA was contracted to design and manufacture a ROV-deployable version of the permanent linear actuator override tool. Detailed design and analysis of the tool were completed. FMECA (Failure Mode, Effects and Criticality Analysis), TRAP (Technical Risk Assurance Process) and TRC (Technical Risk Categorisation) were carried out following API17Q and API17N.

Additional features of the ROV-deployable PCOL system include:

- Depth rating 3050m

- Designed to be installed by ROV in high-current condition using Tool Deployment Unit (TDU)

- Design incorporating a novel engagement, locking and secondary locking functionality for quick installation in one seamless operation

- Up to four Override Tools can be installed on one XT. Two Override Tools can be controlled by one Auxiliary Skid.

- Powered supplied from XT SCM (Subsea Control Module) with 5000 psi working pressure