Project Overview

The Sole Development Project was comprised of drilling two subsea production wells in the Sole Field approximately 40km offshore in the Gippsland Basin. It also involved a subsea tieback via the 65km production pipeline and umbilical from the subsea wells to the existing Orbost Gas Plant.

The shore crossing included a Horizontal, Directionally Drilled (HDD) micro tunnel. A 12” diameter pipeline was then installed from the Orbost Gas Plant to the HDD exit point with a 520 m ‘tail’ laid on the seabed in approximately 20m water depth.

This tail protruding from the HDD exit was exposed to high currents and extreme wave loading in the notorious shallow water of Bass Strait. It needed to be stabilized for winter storms prior to the installation of the main production pipeline in the next season. Due to the mobile sea bed, the pipeline and stabilisation solution also had to be resistant to scour.

If that wasn’t challenging enough, the remote location restricted the available intervention vessels to a couple of local compact DSVs, typically with tight back decks and limited crane capacities.

To solve these challenges, Cooper Energy approached us because of our extensive track record in delivering custom high-performance stabilisation solutions, tailored specifically to small vessel operations in remote locations.

MMA's Solution

The first step to solving the challenge was to develop a stabilisation method capable of being installed by a compact DSV.

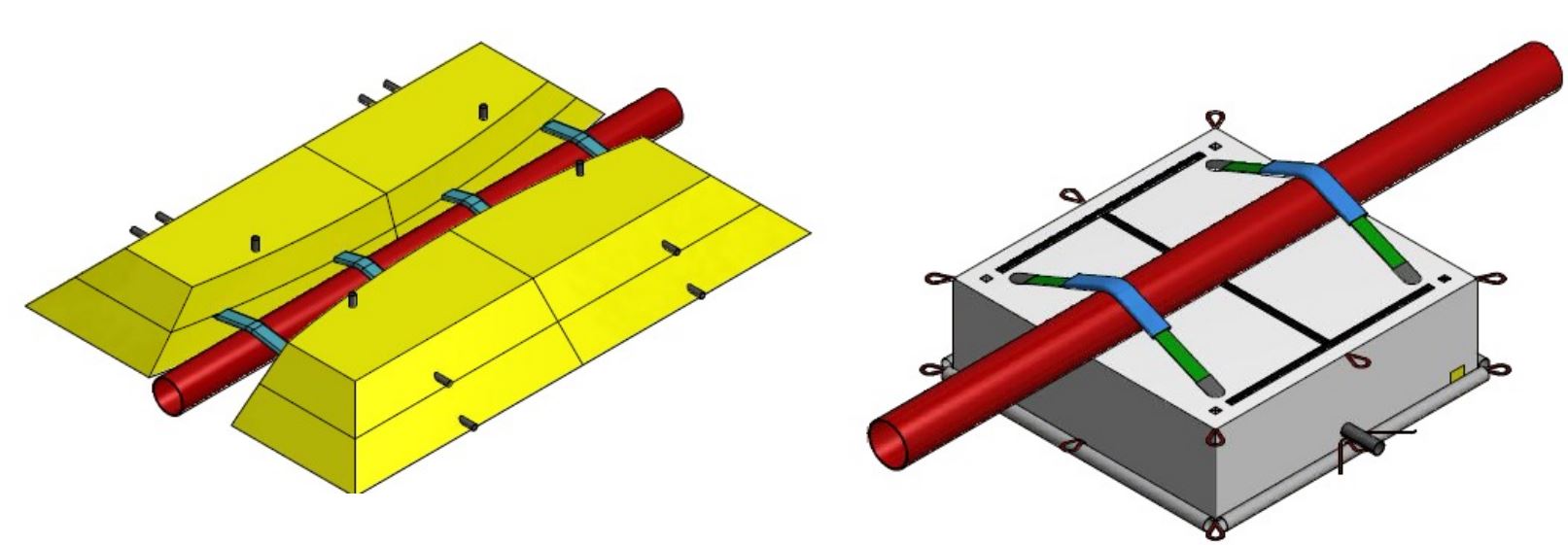

This meant that heavy precast solutions were not viable as the deck and crane capacity was not available to transport and install the required weight. So, we specified a pumped formwork solution that fit within the deck and crane capacities of the vessel.

Secondly, we addressed the stability of the system in the high environmental loading with our proprietary, heavy density (HD) grout. Achieving a specific gravity of 3.5Te/m3, this specialist grout delivers over 2.5 times the stability of standard grouts.

The HD grout was prepacked onshore in 1Te bulk bags, delivered to the vessel and then loaded offshore, straight into our marinized batch plant, SPM5000. The SPM5000 planetary pan mixer is capable of batching high density grouts containing coarse aggregates. It comes with an integrated 70bar piston pump which is capable of pumping HD grouts long distances through hoses underwater.

Divers were able to easily handle the custom formworks into position and connect the hoses from the batch plant to inflate them in situ, successfully stabilising the pipeline tail.

Outcome

The solution was delivered on schedule from a locally available compact DSV. The 57m dive support vessel was loaded with the airdive equipment, batching plant and dry bulk grout.

Six formworks were inflated at four locations including two pairs of bolster style forms and two hybrid span supports with integrated tie-downs.

Technical Details

| Water Depth |

20m |

| Pipeline Diameter |

12" |

| Grout Density |

3,500kg/m3 |

| Vessel Length |

56.8m |

| Crane Capacity |

21Te |

Key Equipment / Installation Method

SPM5000 Batch Plant Turn Table Custom Formworks

MMA Innovation / Value Added

The use of HD grout instead of Portland cement reduced the volume of grout required by almost 50% compared to conventional marine grouting methods. This meant the scope could be delivered in one trip providing further savings on vessel spread costs. The experienced crew utilised our SPM5000 grouting equipment which enables all grout works to be completed in just four days, despite difficult weather conditions restricting daily grouting times to as little as three hours.